Faculty

Networking for Artifact

WAN Yi

- Position

- Lecturer

- Affiliation

- Department of Systems Innovation, Faculty of Engineering, The University of Tokyo

- Keyword

- Material engineering, Experimental evaluation, Modeling analysis, Carbon fiber reinforced composites

- wan-yi(at)cfrtp.t.u-tokyo.ac.jp※Please replace (at) with @ and send mail.

Feature Evaluation, Property Control, and Social Implementation of Advanced Composite Materials

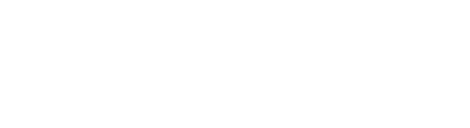

Comprehensive evaluation of molding process, internal geometry, and mechanical property

Feature evaluation, property control, and social implementation of advanced composite materials are crucial to solving the environmental, energy, and rescores issues to achieve GX and SDGs of our society. Discontinuous CFRP is considered the inevitable solution for complex-shape molding, high-cycle molding, and CF-recycle application. However, extremely complicated internal fiber geometry is generated during the fabrication process of discontinuous CFRP, hence severely decreasing the prediction accuracy with the traditional mechanical models. To provide a feasible methodology and promote the social implementation of this material, comprehensive evaluations of the molding process, internal geometry, and mechanical property are carried out.

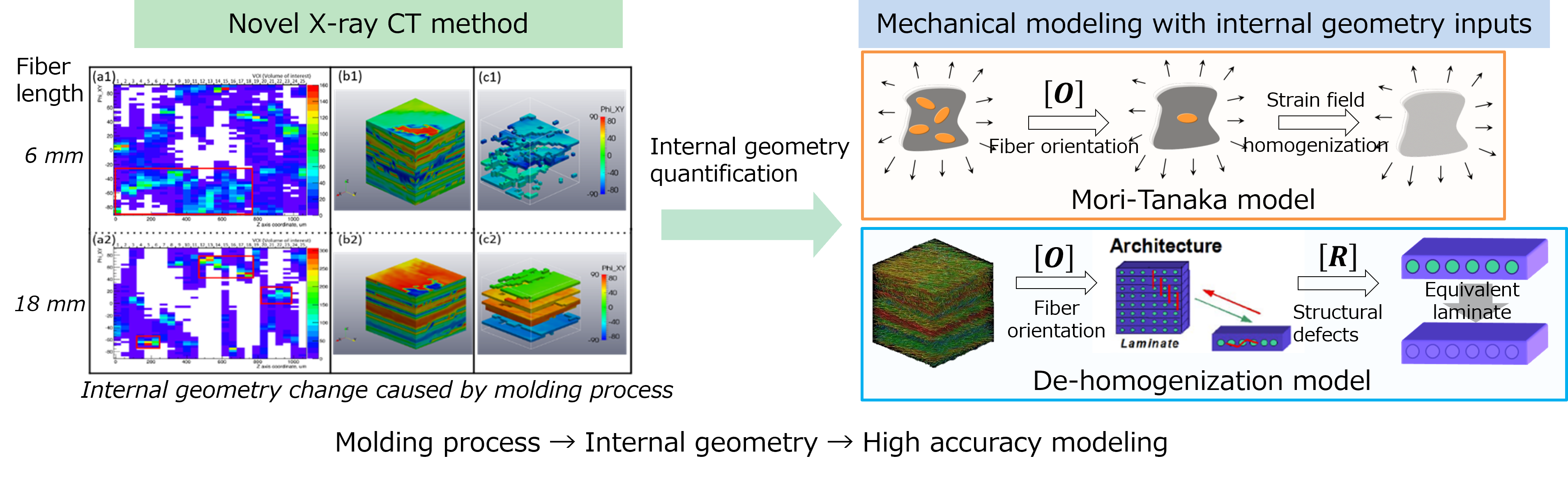

Statistical approach on material property

High-performance discontinuous CFRP demonstrate strong property-variation. The evaluation and control of this property-variation are unneglectable for structural applications. We focus on the evaluation of material properties and their variations by applying statistical methods (e.g., Monte-Carlo model) under the comprehensive consideration of the molding process, internal geometry, and mechanical property.

Material engineering and social implementation of advanced materials

To achieve a fast and low-cost social implementation, not only the analysis of theories and technics for evaluating and controlling the detailed mechanical properties but also the synthesis of the approximation and systematization of those theories and technics are carried out to fitting the overall vision of the application target.